It is sure you are habituated to coexist in your daily life with LED technology, sometimes even unknowingly. Lighting of that restaurant you were and liked so much, the atmosphere so cozy of that hotel where you spent the holidays… LED technology is able to create unforgettable, healthy and economical and energy efficient environments. But … have you ever ask you how a LED is made? At Goodwork we tell you.

What is a LED?

A LED (an acronym for “Light Emitting Diode”) is a semiconductor diode whose main characteristic is to convert the low-voltage electric current through its chip into light. The first LED was developed in 1927, although it was not until the decade of the sixties when it was used for commercial purposes. Since then, research in this sector has not ceased and LED lighting is now considered the most efficient form of lighting, being used in many devices that bring a higher quality of life to our day to day.

At its beginnings, the main use of this technology was limited to the manufacture of the red LED, which was given the use of indicating whether an electrical or electronic equipment was connected to the electric current, or was in functioning. Later they began to make informative panels with LED lighting.

Innovation has made it possible today to manufacture LEDs with the ability to reproduce all the colors of the visible spectrum of the human eye. At Goodwork as an LED manufacturer, we are continuously working on LED chip design and research that significantly increases its light efficiency.

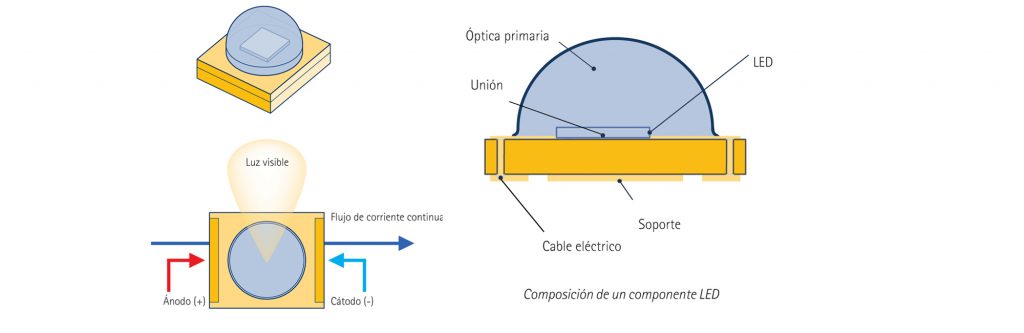

From a physical point of view, in the manufacture of a LED, we find a miniaturized bulb, devoid of filament or any other type of harmful element or material, which is one of the great advantages of LED lighting over other technologies which pollute the environment. A LED has a solid construction, so it has greater resistance to shock and vibrations.

The color emitted by each diode depends fundamentally on the semiconductor material that has been used in the manufacture of the LED. Each chemical compound of the semiconductor material used in the manufacture of an LED allows the emission of a light of a specific color corresponding to a particular wavelength of the electromagnetic spectrum visible to the human eye.

The light-emitting chip is the main part of an LED and is enclosed in a transparent or tinted polyepoxide (resin) wrapper or capsule of the same color as the light it emits. These can have different shapes and sizes. From the chip split two terminals that cross its base and go outside to connect to a direct current electric circuit, so that the LED is directly polarized. When the LED is new, the shortest terminal corresponds to the negative (-) pole of the chip, while the longest corresponds to the positive (+) pole.

The chip is the main component of LED lighting and its quality depends not only on the consumption and the duration of the lamp but also the color and intensity of the light./

How is a LED manufactured?

The manufacture of an LED is based mainly on the creation of the chip. The substrate or semiconductive base is elaborated on which the rest of components will be applied later.

This base is a wafer of about 15 cm in diameter, usually of silicon carbide or sapphire that is formed in a chamber at a high temperature and pressure and on which different elements are worked depending on the characteristics of the light that If desired. Mainly:

- Indium and Gallium Nitride (InGaN): for blue light.

- Aluminum, indium and gallium (AllnGaP): for warm light with yellow, orange and red tones.

- Gallium phosphide (GaP): for yellow and green light.

High temperatures and pressure causes the elements to liquefy to a solution. A liquid layer of boron oxide (liquid encapsulation) is used to escape the gas. When the elements are mixed in a uniform solution, a bar is introduced and it is removed very slowly. The solution is cooled and the crystallizations formed at the end of the bar.

The wafers are cleaned by a chemical and ultrasonic process. It is very important that all dirt and dust are removed for best results.

Then comes the process of epitaxy, which is used in the manufacture of an LED with all kinds of chips, in which the layers necessary for the correct functioning of the LED with these deposited materials are formed.

Then the wafer is divided into tiny rectangles, which are the chips themselves. These chips undergo rigorous quality tests to verify that the intensity, color and brightness of the light is the required. At Goodwork, as LED manufacturers, we use high quality and efficient chips, such as the Nichia or CREE, which use materials that offer superior performance. Goodwork LED strips, for example, reach a power and efficiency level of a total of 5.670 lumens / meter and a light efficiency of 236 lm / w, higher than the average LED manufacturers in Spain.

Do not hesitate and move to LED with Goodwork.